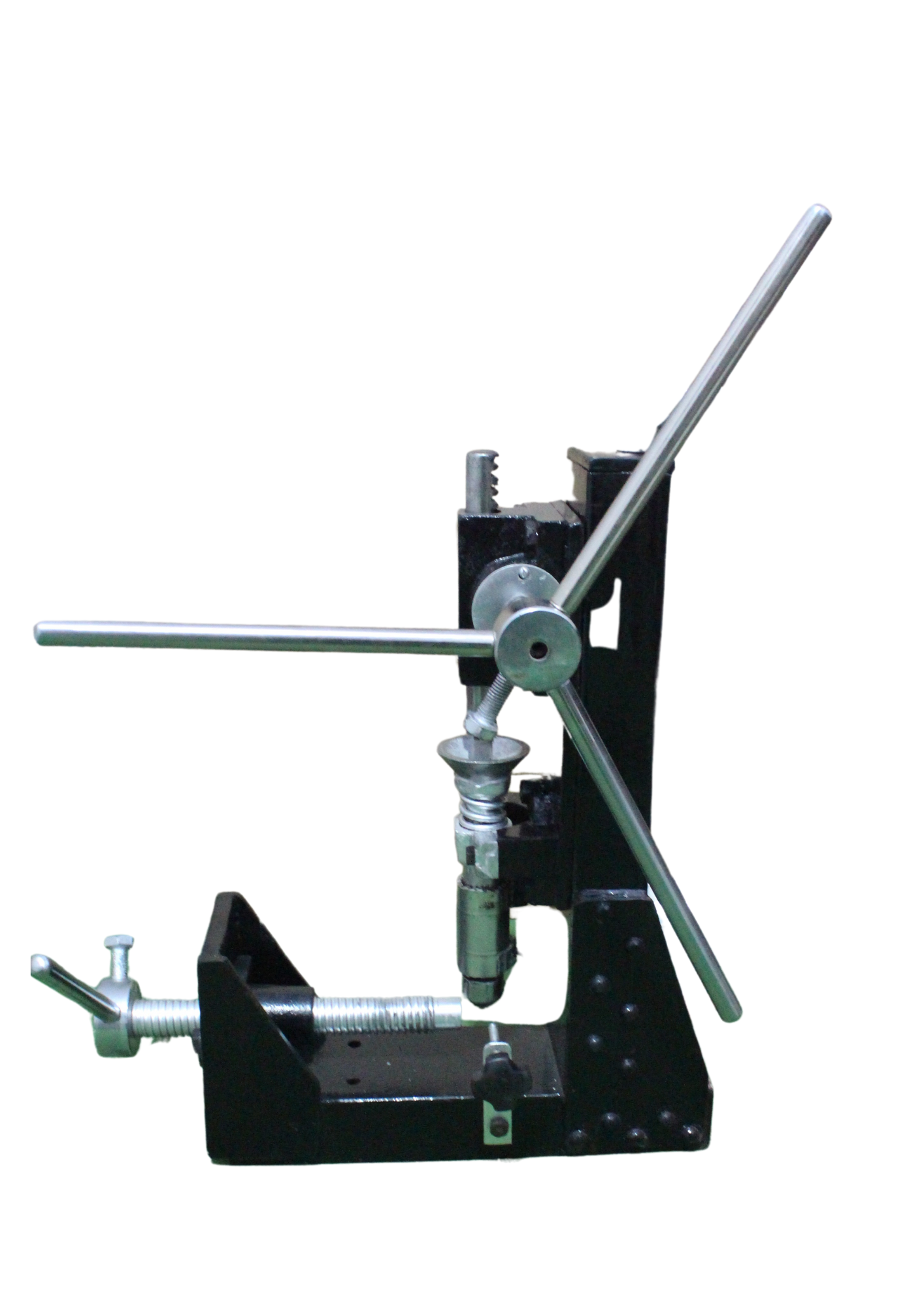

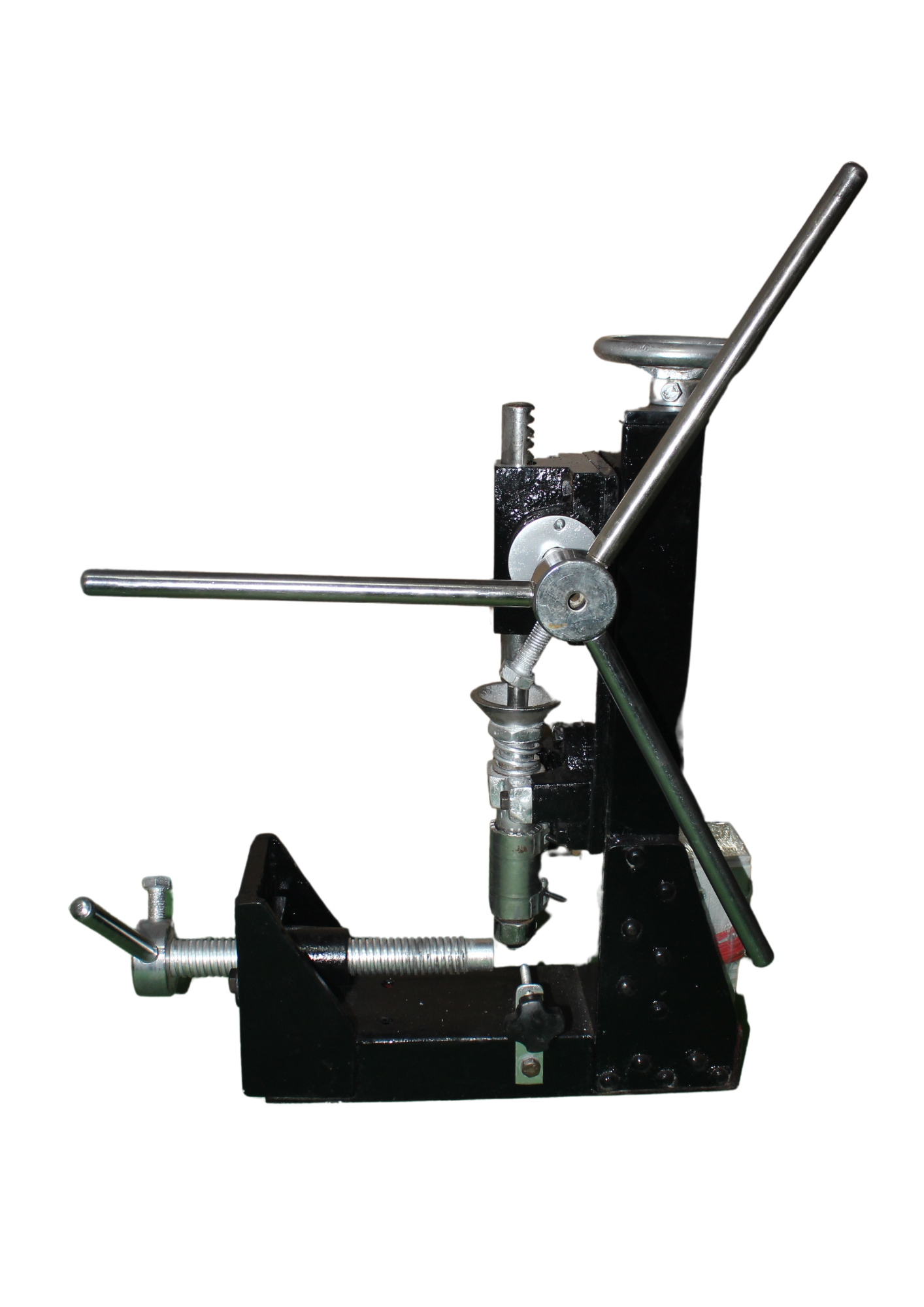

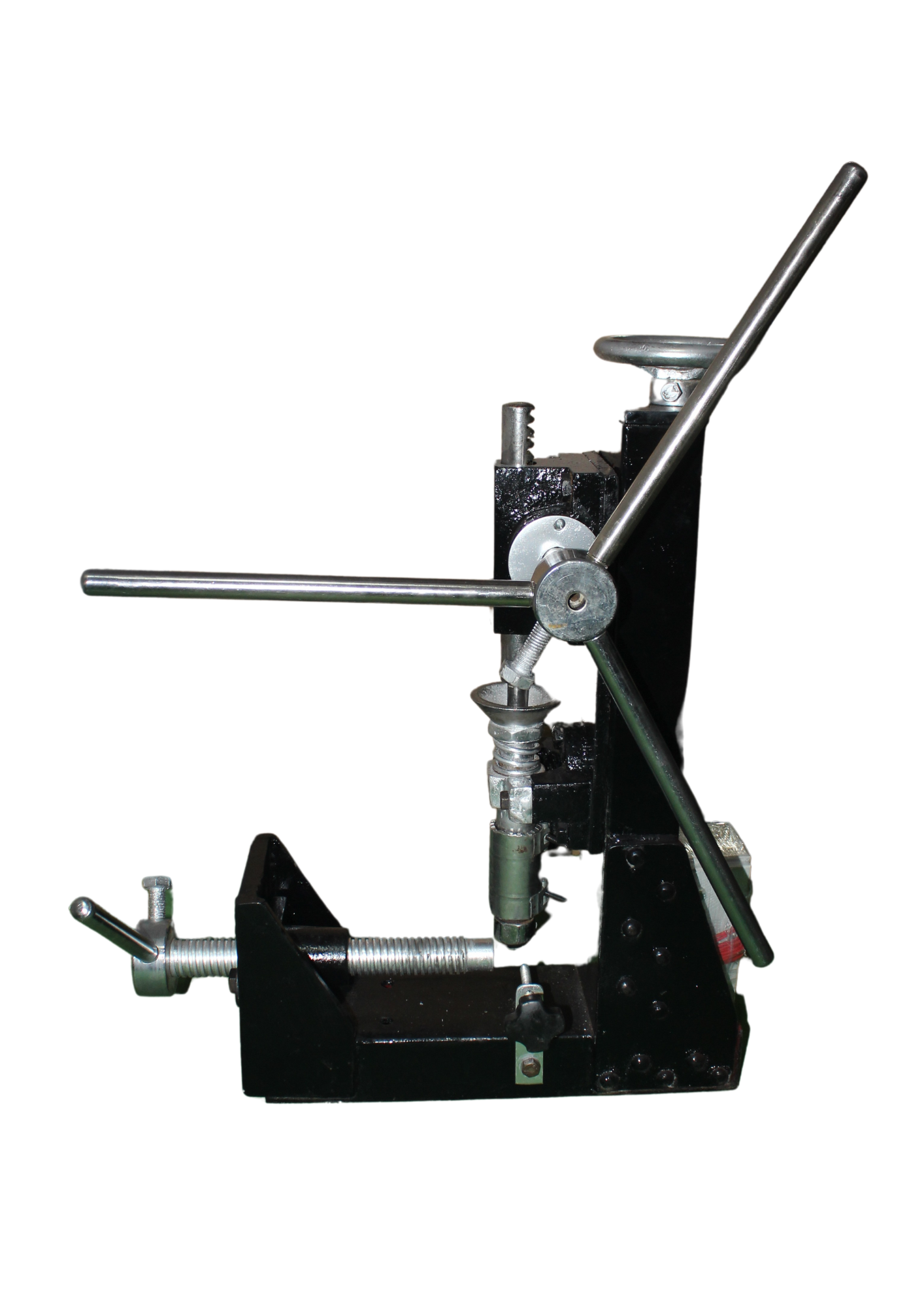

HAND MOLDING MACHINE 20gm

Product Details:

- Frequency 20 Hertz (HZ)

- Voltage 220 Watt (w)

- Product Type Filling Machine

- Technology Other

- Power Source Electricity

- Operating Type Manual

- Power 240 Watt (w)

- Click to View more

HAND MOLDING MACHINE 20gm Price And Quantity

- 1 Pieces

- 11999.0 INR/Piece

HAND MOLDING MACHINE 20gm Product Specifications

- 60 Kilograms (kg)

- Other

- Other

- Manual

- 240 Watt (w)

- Electricity

- 1 PSI

- NA

- Filling Machine

- 1 Meter (m)

- 20 Hertz (HZ)

- 220 Watt (w)

- 100 Pcs/hr

HAND MOLDING MACHINE 20gm Trade Information

- INDIAN

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- 100 Pieces Per Week

- 3 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- APS STAR DELHI

- Asia

- All India

Product Description

-

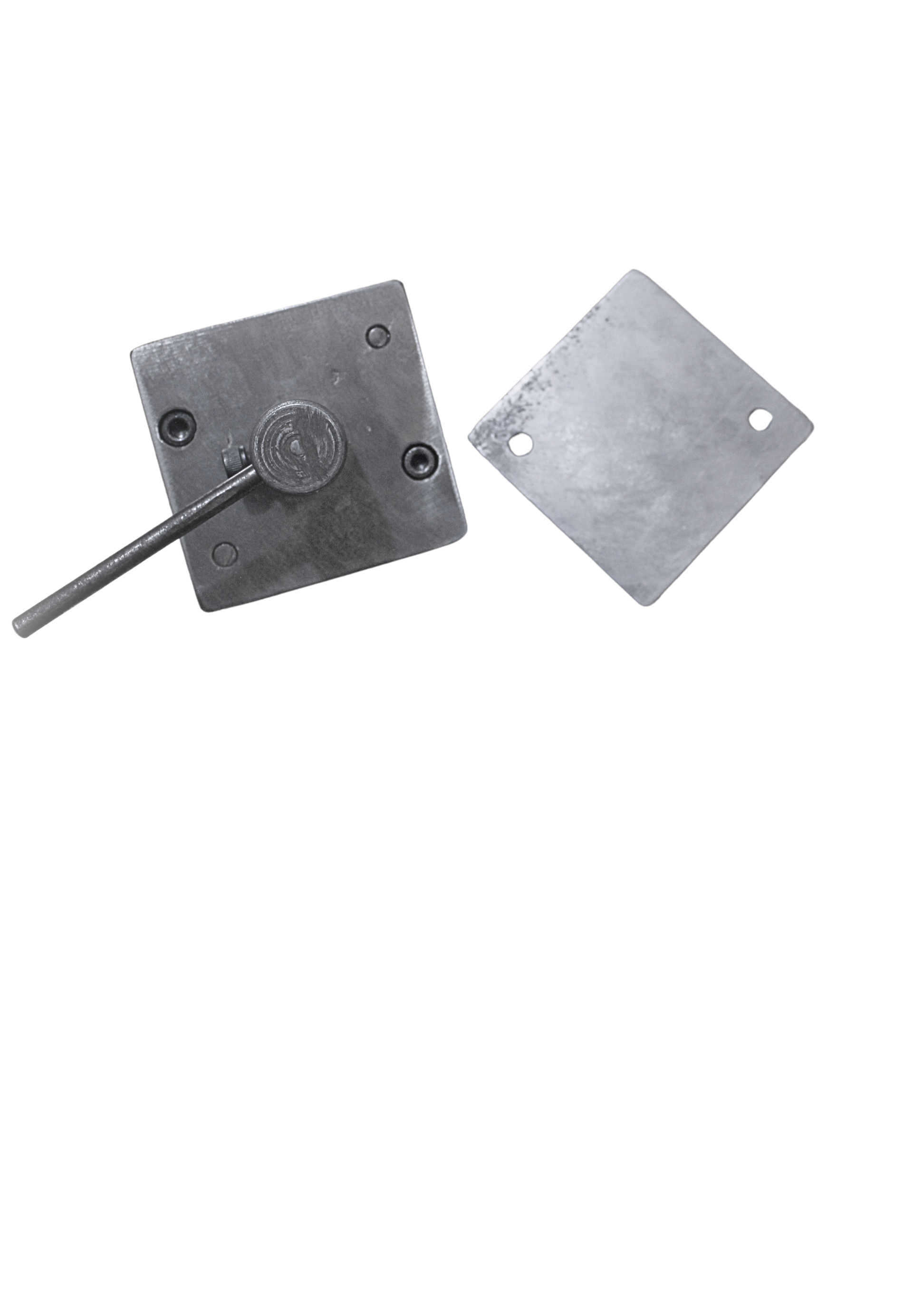

Functionality: It allows operators to shape materials like clay, metal, or plastic by pressing or molding them into a specific form, often using a mold cavity.

-

Manual Operation: The machine requires human input for operation, typically involving hand-based adjustments or force to shape the material.

-

Applications: Commonly used in industries like foundries, ceramics, toy manufacturing, and crafts, where precision and custom shapes are needed for small-scale production.

-

Components: The machine usually includes a mold, pressing mechanism, and adjustable settings for different shapes or sizes.

-

Versatility: Hand molding machines are ideal for low-volume production or custom work due to their flexibility in producing unique or intricate designs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry