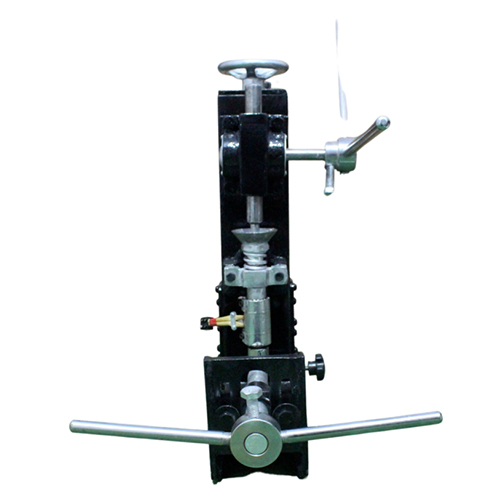

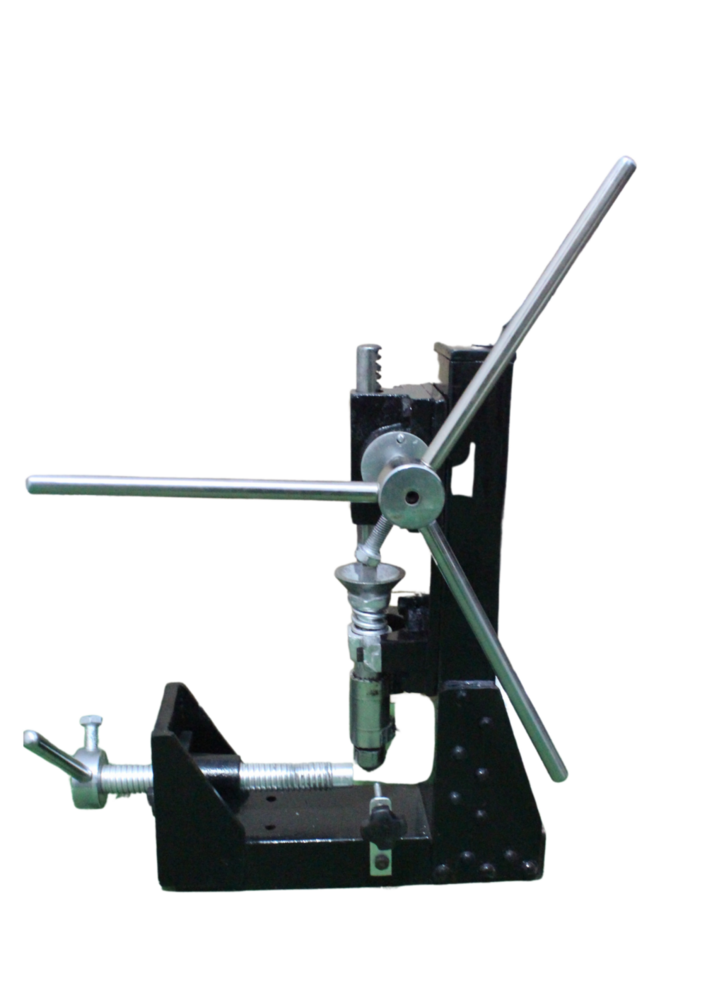

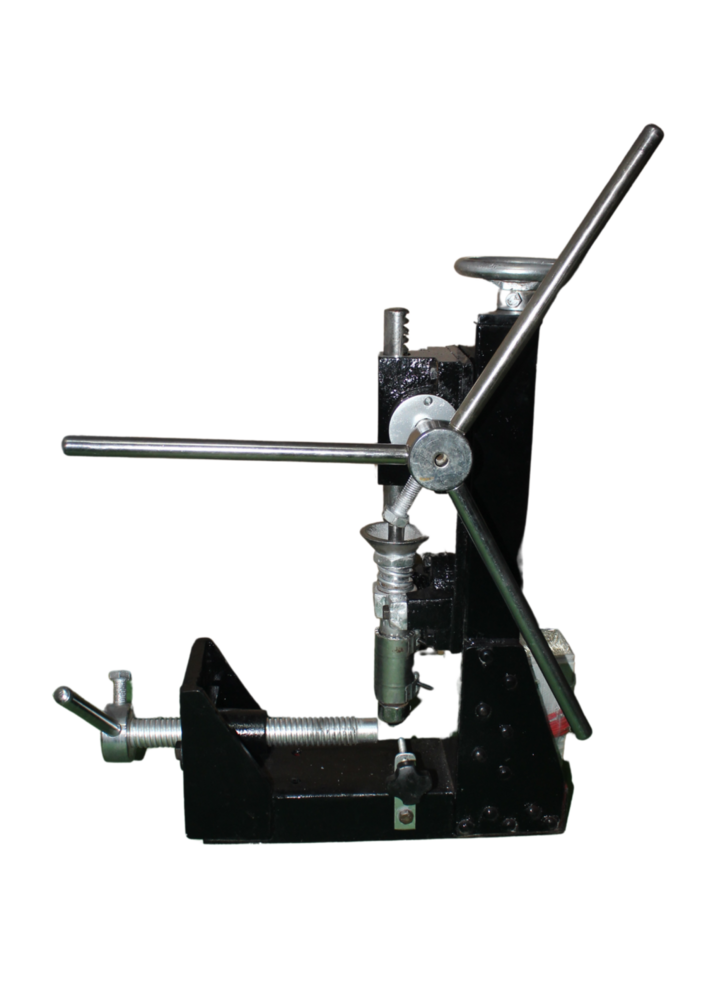

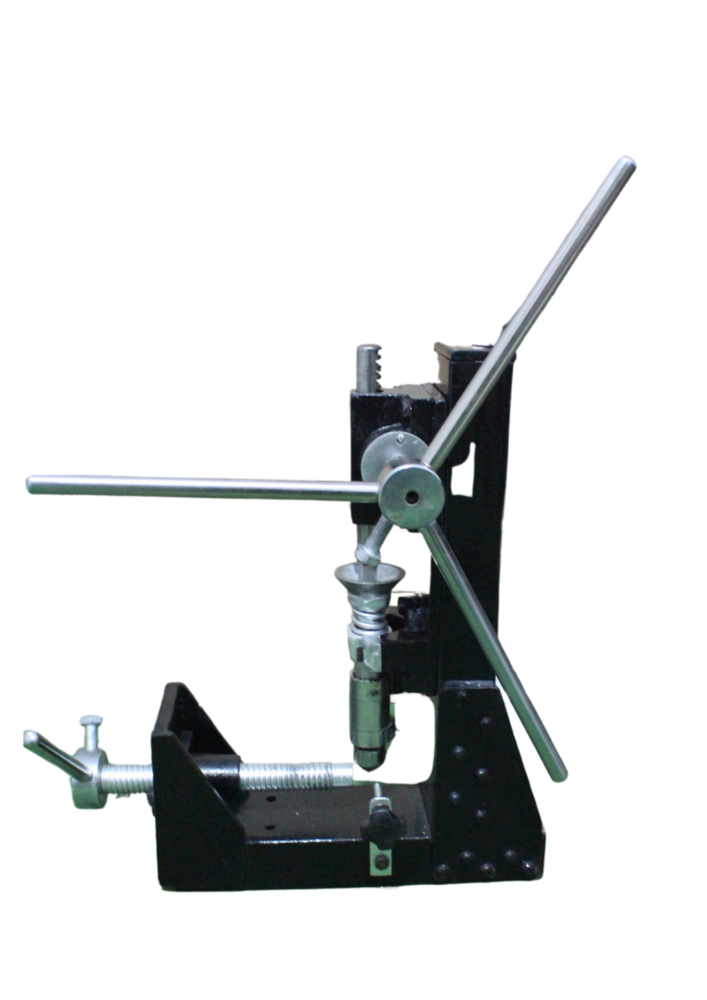

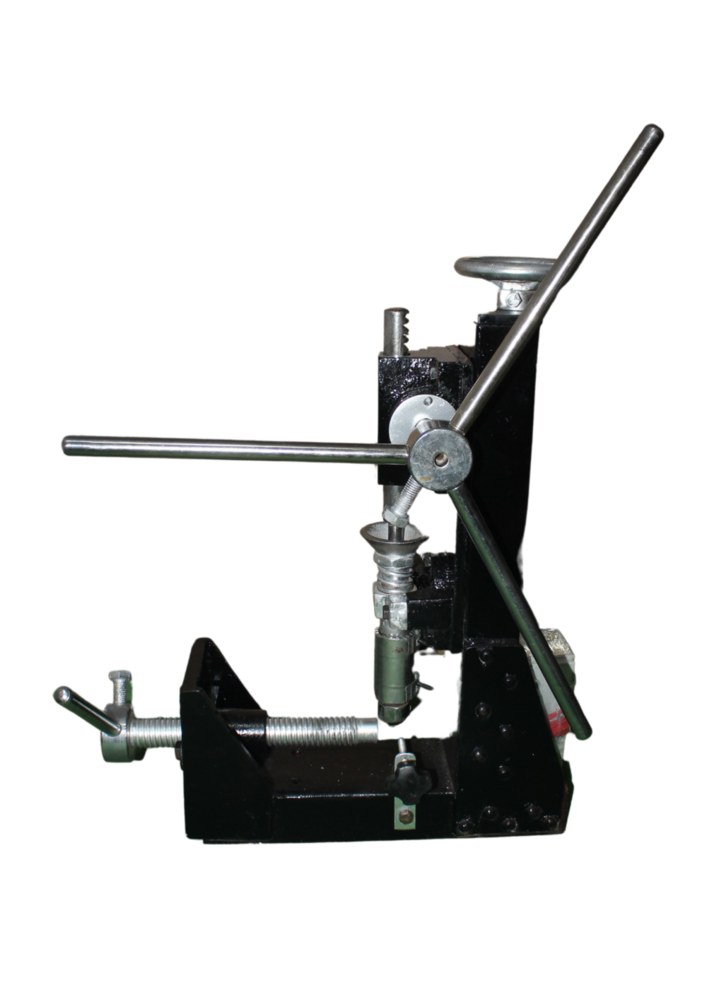

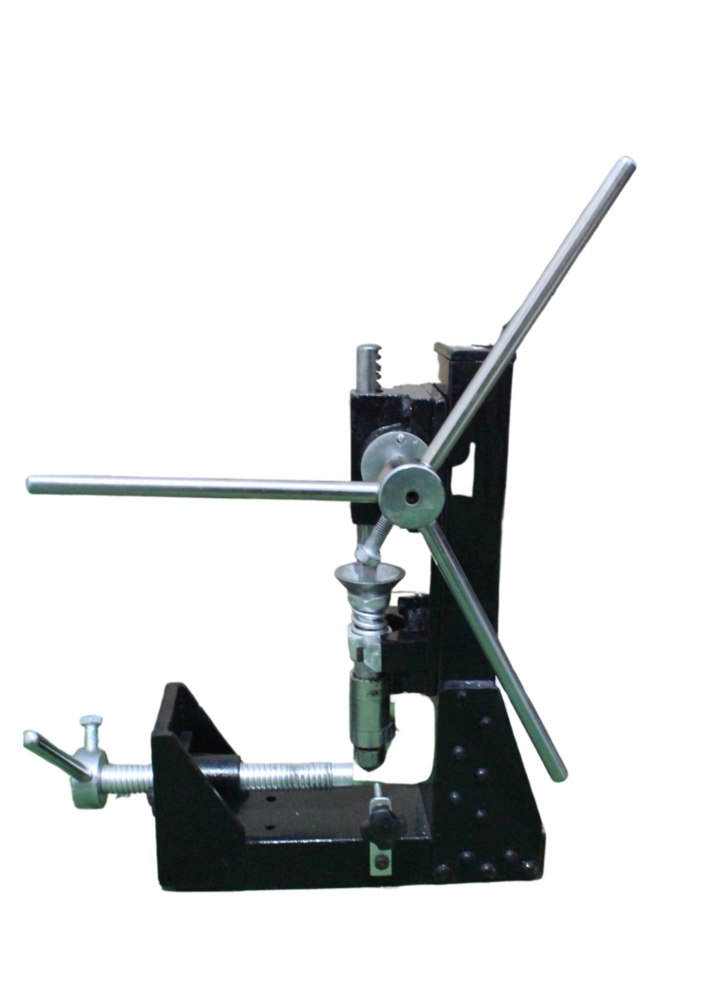

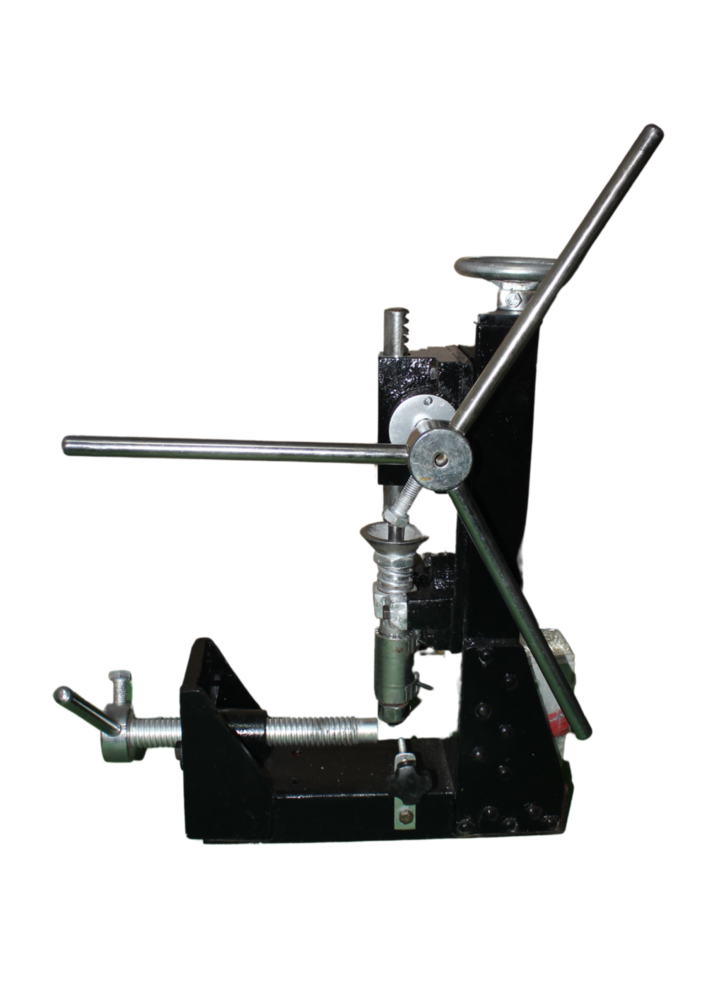

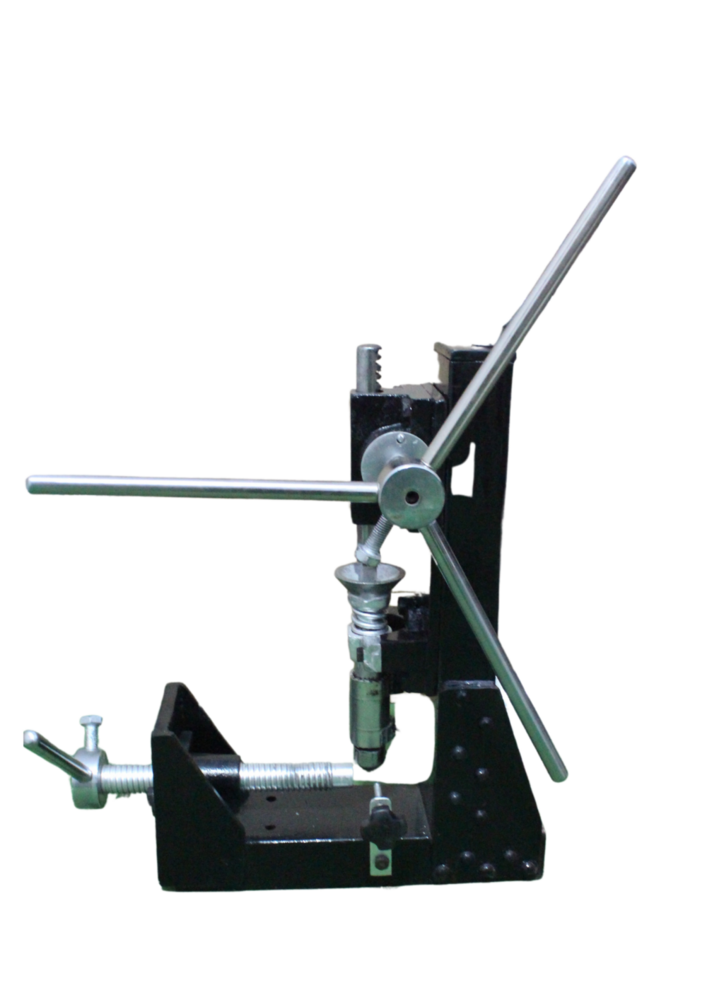

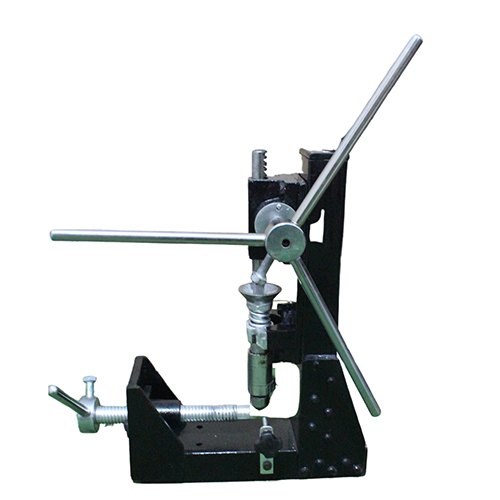

HAND MOLDING MACHINE

Product Details:

HAND MOLDING MACHINE Price And Quantity

- 1 Piece

- 11990 INR/Piece

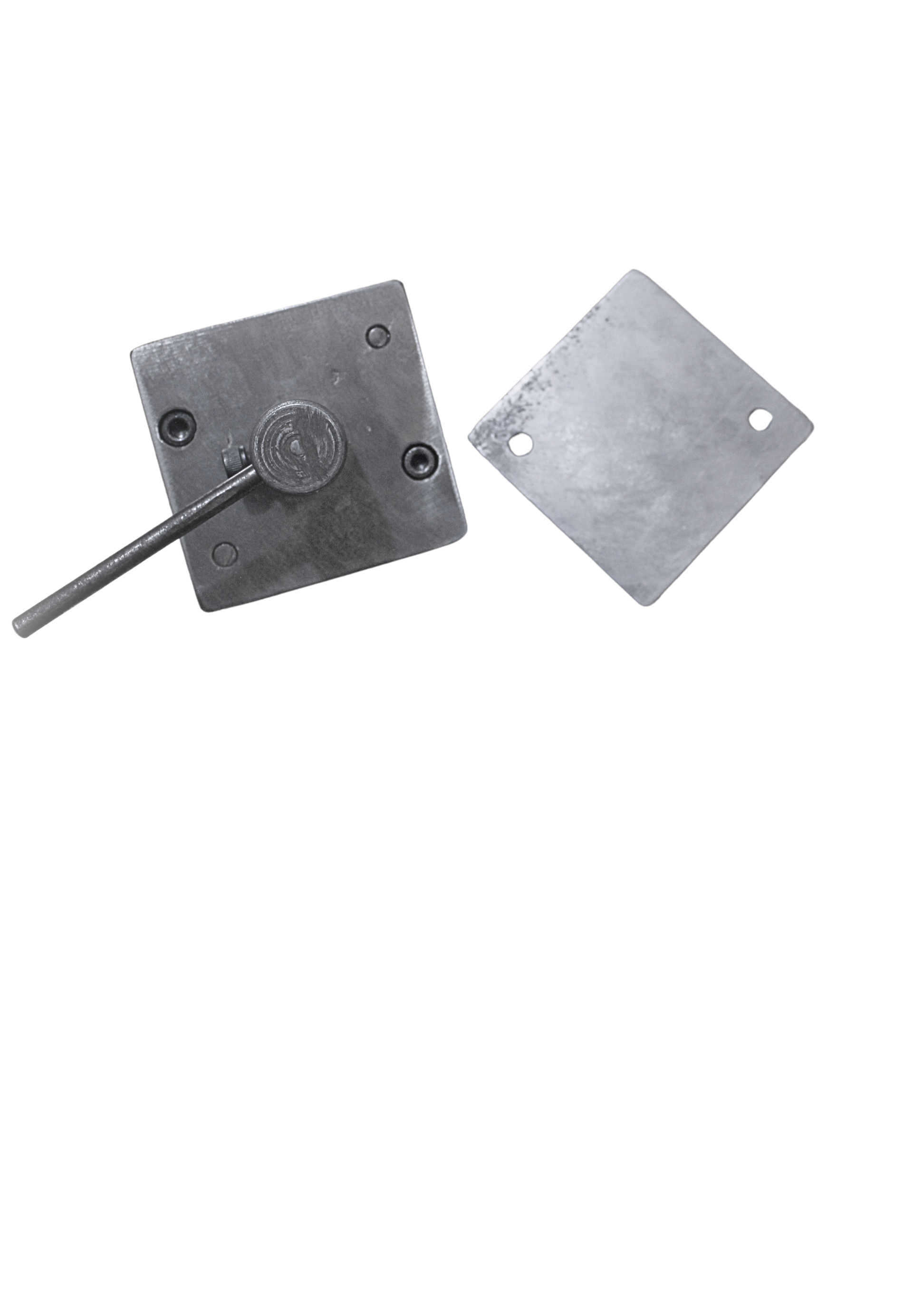

Product Description

-

Injection Molding Machine: This is the most common type used in the plastics industry. It injects molten plastic into a mold cavity under high pressure. The plastic is then cooled to form a solid part. It is used to produce small, precise, and complex shapes.

-

Blow Molding Machine: Used to create hollow plastic parts, such as bottles and containers. The machine inflates a softened tube of plastic inside a mold to form the desired shape.

-

Compression Molding Machine: Used for molding rubber and thermosetting plastics. The material is placed in a mold cavity and compressed by a heated press. The material is then allowed to cure, taking the shape of the mold.

-

Rotational Molding Machine: This process is used to make large hollow parts, such as tanks and containers. The mold is heated and rotated along two perpendicular axes while the material (usually plastic powder) melts and coats the inside of the mold.

-

Thermoforming Machine: In this process, a sheet of plastic is heated until it is soft and then stretched over a mold to form a specific shape.

Key Components of a Molding Machine:

- Injection Unit: This is responsible for melting and injecting the material into the mold.

- Clamping Unit: Holds the mold in place during the injection process, and provides the force required to open and close the mold.

- Mold: The custom-designed cavity that defines the shape of the finished product.

- Hydraulic System: Powers the injection and clamping units, providing the force needed for the molding process.

- Control System: A computer or manual interface used to adjust the machine's settings, monitor performance, and ensure quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry